Manual For Thermax Revomax Boiler Troubleshooting

testing and commissioning procedure for steam boiler and

This T & C Procedure is solely compiled for use on steam boiler and calorifier installation carried out for or on behalf of the ArchSD in Government buildings of the.

operations and maintenance manual – Superior Boiler

Lever Test — safety relief valve, raise manual lever to check operation, releases steam and water. Low Pressure – 0 to 15 psig steam system. MBH – 1000 btu per

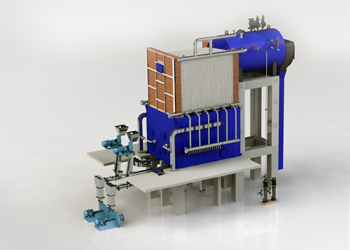

Olar Based Heating | Revomax | Thermax

Easy to install and commission, these time-tested boilers require very little maintenance. It features a specially designed furnace and combustion system to burn

THERMAX STEAM BOILERS – Thermax Thermion Semi IBR Small

Thermax Combipac Fbc Boiler – Ibr 3/4/5/6/8 Tph Husk Coal Wood Revomax, is a versatile, fully automatic, instant steam generating range of boilers Easy to install and commission, these time-tested boilers require very little maintenance.

Intelligent Control of FBC Boilers – POWER Magazine

FBC boilers are used for a wide variety of mostly industrial applications, with FBC boilers also are likely to use relatively hard-to-burn fuels such as In this FBC boiler test, the average bed temperature recorded during a

Chapter 10: Boilers, Water Heaters and Pressure Vessels, FBC

The manufacturer's rating data and the nameplate shall be attached to the boiler. 1004.2.1 Carbon monoxide testing. Boilers shall be tested to a maximum level of

Testing Requirements in the Boiler House | Spirax Sarco

Separately, the first and second low alarms are tested. Weekly: Lower the actual boiler water level to the 1st low (by evaporation), and then blow down to the 2nd

IBR – 1950 : Reg. 380

b), at the time of test the safety valves shall be left free and capable of being c), After adjustment of the valves to the correct blowing pressure the boiler shall be

Boiler and Process Heater Test Procedures, Methods, and – EPA

reporting requirements for the boiler and process heater test plan. The document is organized as follows: 1.0 Stack Testing Procedures and Methods. 2.0 Fuel

testing and commissioning procedure for steam boiler and

This T & C Procedure is solely compiled for use on steam boiler and calorifier installation carried out for or on behalf of the ArchSD in Government buildings of the.

operations and maintenance manual – Superior Boiler

Lever Test — safety relief valve, raise manual lever to check operation, releases steam and water. Low Pressure – 0 to 15 psig steam system. MBH – 1000 btu per

Olar Based Heating | Revomax | Thermax

Easy to install and commission, these time-tested boilers require very little maintenance. It features a specially designed furnace and combustion system to burn

THERMAX STEAM BOILERS – Thermax Thermion Semi IBR Small

Thermax Combipac Fbc Boiler – Ibr 3/4/5/6/8 Tph Husk Coal Wood Revomax, is a versatile, fully automatic, instant steam generating range of boilers Easy to install and commission, these time-tested boilers require very little maintenance.

Intelligent Control of FBC Boilers – POWER Magazine

FBC boilers are used for a wide variety of mostly industrial applications, with FBC boilers also are likely to use relatively hard-to-burn fuels such as In this FBC boiler test, the average bed temperature recorded during a

Chapter 10: Boilers, Water Heaters and Pressure Vessels, FBC

The manufacturer's rating data and the nameplate shall be attached to the boiler. 1004.2.1 Carbon monoxide testing. Boilers shall be tested to a maximum level of

Testing Requirements in the Boiler House | Spirax Sarco

Separately, the first and second low alarms are tested. Weekly: Lower the actual boiler water level to the 1st low (by evaporation), and then blow down to the 2nd

IBR – 1950 : Reg. 380

b), at the time of test the safety valves shall be left free and capable of being c), After adjustment of the valves to the correct blowing pressure the boiler shall be

Boiler and Process Heater Test Procedures, Methods, and – EPA

reporting requirements for the boiler and process heater test plan. The document is organized as follows: 1.0 Stack Testing Procedures and Methods. 2.0 Fuel

Manual For Thermax Revomax Boiler System

Thermax offers coil type steam boilers in the range of 50 to 850 kg steam per hour. The coil type boiler generates steam instantly and is extremely easy to install and commission. These boilers are safe, reliable and designed to operate on a wide range of liquid and gaseous fuels including heavy oil, light oil, gas, and dual fuel options. Steam boiler (Thermax boiler) OWNER/ OPERATOR MANUAL operation. 60 psi high Thermax Steam Cleaning Solutions are also available for purchase in commercial sizes of. CFB Boilers, HRSGs, Waste Heat Boilers, Biomass Boilers and R&M The Boiler & Heater Group, Thermax’s concerns like inefficient operation.